Ethylene and Pathogen Control

for Walk-in Coolers

Reduce wastage and maximise profits from delicate fresh produce

held in mixed produce cold rooms.

Walk-in Coolers

The quality of produce kept in walk-in coolers may suffer in many aspects due to improper storage conditions. Mould, rot, premature ripening, shrivel, and weight loss are among the undesirable effects. While high relative humidity helps to eliminate shrivel and weight loss, the challenges caused by airborne bacteria and ethylene (a natural ripening hormone) require a special treatment.

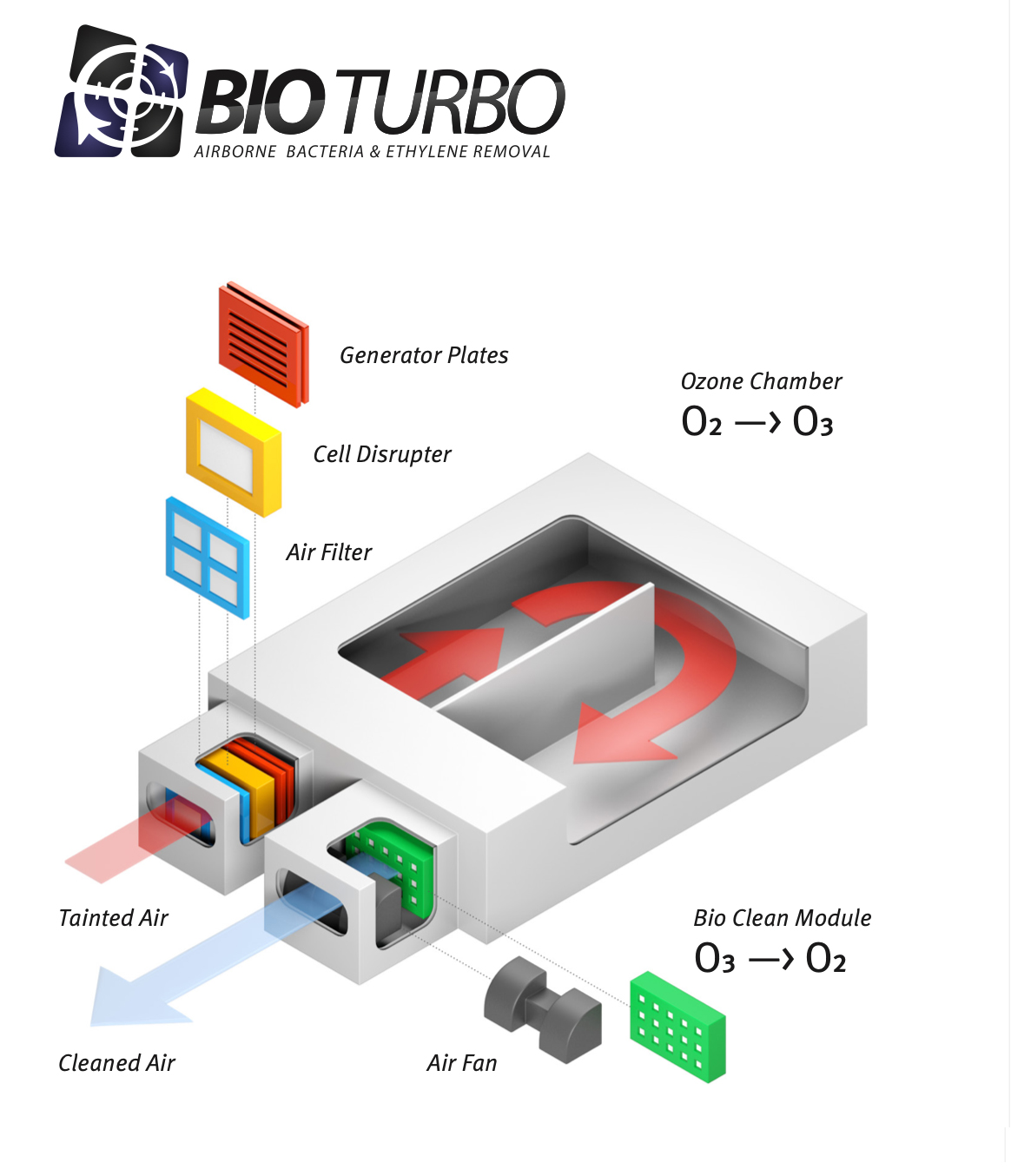

This is when the positive effects of Bio Turbo are most beneficial. It uses a patented four stage process to eliminate ethylene gas, airborne bacteria and mould spores. It successfully prevents mould growth, eliminates unpleasant odours, and reduces unnecessary losses while preserving natural freshness and quality.

- Extends Produce Shelf Life

- Eliminates Mould & Fungi

- Kills Bacteria & Viruses

- Removes Ethylene

- Decreases Odours

STAGE 1: AIR FILTER

The air filter removes dust and visual particles from the air.

STAGE 2: CELL DISRUPTER

An anti-microbial chemical is applied to the surface of a specially designed disrupter. It works by rupturing the outer membrane of the cells that make up these airborne pathogens. With efficiency rates of 99.5%+, this process stops their normal life development, thus destroying the cells.

STAGE 3: OZONE CHAMBER

This chamber uses the positive effects of ozone to eliminate ethylene gas. The ozone is safely contained within this chamber and not dispersed throughout the storage area.

STAGE 4: BIO CLEAN MODULE

In this final stage, a catalyst is used to change the ozone into clean oxygen. The catalyst creates a reaction that breaks down the ozone molecule. From here the clean oxygen is released back into the environment.

OTHER PRODUCTS IN RANGE

Post-harvest

Transport

Storing Flowers

Speak to the AUSPAC Biotechnologies team today!

Chat to us about extending your shelf life and produce quality