Ethylene and Pathogen Control for Transportation

Premium protection for high value fresh produce while in cold transport containers.

Transportation Control

Providing proper transportation conditions for fresh perishables is always important. A rule of thumb is to use ethylene and airborne bacteria protection every time refrigeration is used. Even when the time in transit is too short for moulds or bacteria to develop, pathogens can still inoculate produce and develop later.

Prevention is easy, and helps to delay premature ripening. Bio Turbo uses a patented four stage process to eliminate ethylene gas, airborne bacteria and mould spores. It successfully prevents mould growth, eliminates unpleasant odours, and reduces unnecessary losses while preserving natural freshness and quality.

- Increased profit

- Preserved quality

- Reduced waste

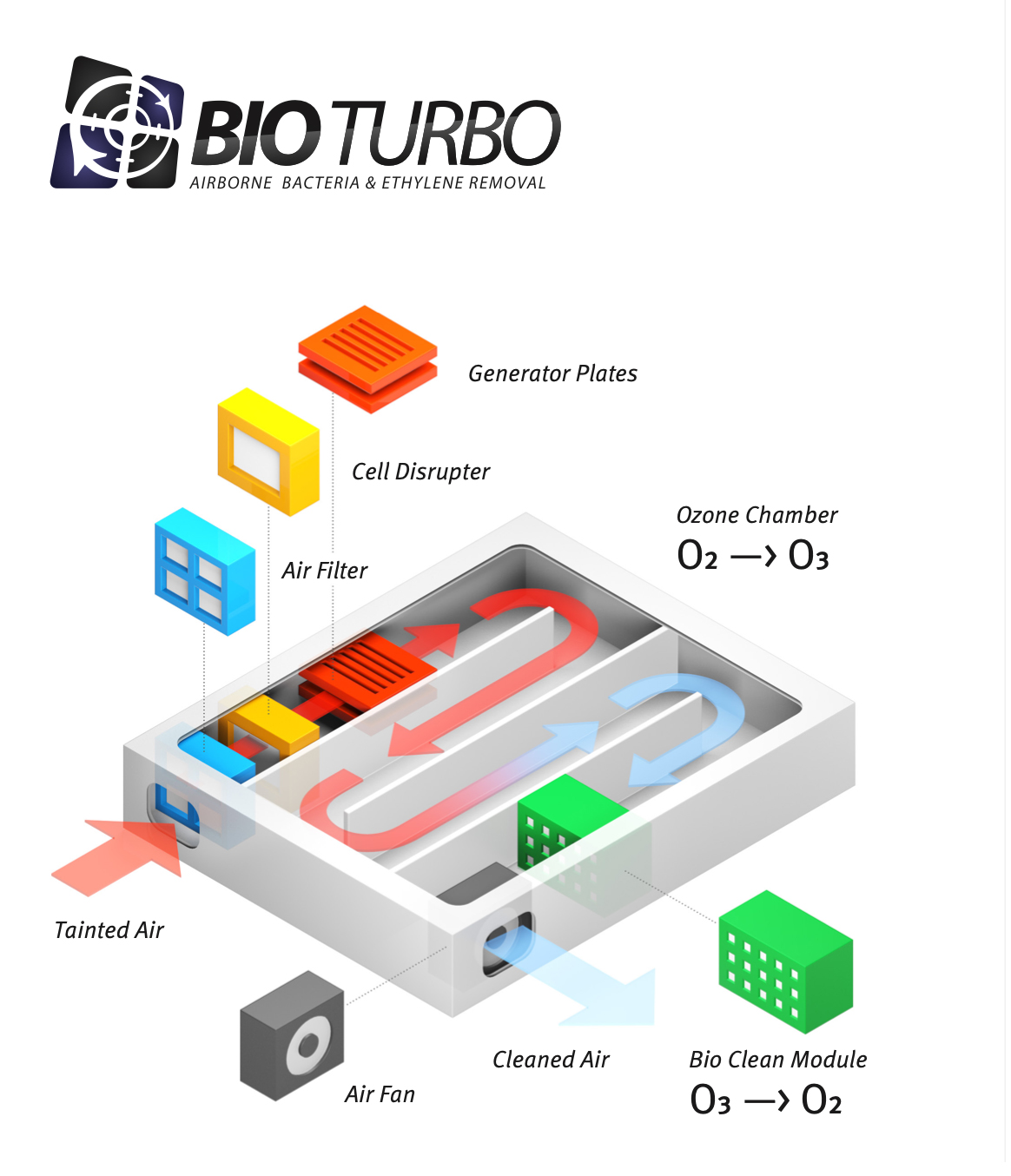

STAGE 1: AIR FILTER

The air filter removes dust and visual particles from the air.

STAGE 2: CELL DISRUPTER

An anti-microbial chemical is applied to the surface of a specially designed disrupter. It works by rupturing the outer membrane of the cells that make up these airborne pathogens. With efficiency rates of 99.5%+, this process stops their normal life development, thus destroying the cells.

STAGE 3: OZONE CHAMBER

This chamber uses the positive effects of ozone to eliminate ethylene gas. The ozone is safely contained within this chamber and not dispersed throughout the storage area.

STAGE 4: BIO CLEAN MODULE

In this final stage, a catalyst is used to change the ozone into clean oxygen. The catalyst creates a reaction that breaks down the ozone molecule. From here the clean oxygen is released back into the environment.

OTHER PRODUCTS IN RANGE

Post-harvest

Walk-in Coolers

Storing Flowers

Speak to the AUSPAC Biotechnologies team today!

Chat to us about extending your shelf life and produce quality