Reduce fresh produce wastage

and increase returns.

AUSPAC Biotechnologies Pty Ltd is an innovative Australian company who are passionate about assisting our clients with maximising fresh produce shelf life and reduce product wastage by minimising the presence of airborne pathogens and ethylene gas from delicate storage and transport environments.

Fresh Produce

Meat

Seafood

Deli

Floral

Wineries

Increase produce yields and reduce product wastage

Fresh produce such as fruit, vegetables, flowers, fish and meat are all susceptible to airborne issues that reduce viability, shelf life, weight, appearance and importantly customer appeal. The process of field to plate is a delicate journey fraught with multiple cold storage and handling points that can impact the volume and value of final product.

The removal of airborne pathogens such as moulds, virus and fungi along with unwanted natural ethylene gas assists anyone dealing with produce to store and maintain their produce fresher for longer periods of time. It also prevents premature ripening, reduces rot and minimises cross contamination issues.

AUSPAC Biotechnologies is a proud authorised dealer of Miatech Inc. who have patented the Bioturbo Systems that removes airborne ethylene and safely kills airborne pathogens in produce cool storage areas.

Flexible Prompt

Delivery and Installation

AUSPAC Biotechnologies are highly experienced in large time sensitive projects and consistently provides a flexible and prompt service for the supply, delivery and or installation of Biotechnology systems.

AUSPAC Biotechnologies delivers you Miatech products that provide a genuine advantage in the highly competitive industry of delivering the freshest of perishables to the marketplace. Maintaining this advantage via consistent stocks of ready to go units and rapid supply of maintenance kits as required is our priority.

Cleans air of mould spores, reducing risk of spread in long store facilities.

Providing the best possible

environment for produce

and workers.

At every level, be it, grower, transport, storage, distribution, retail or manufacturer there is a responsibility to provide the best possible environment to maximise shelf life, meet consumer expectation, and provide staff with the best air quality possible to work in. Wastage and losses can be reduced by mediating the incidence of airborne pathogens and ethylene contamination of valuable produce and the benefits are measured via increased profits. Importantly the reduction of harsh odours in tough produce environments improves the daily work environment of your valuable facility staff.

Priority lines include Apples, Bananas, Broccoli, Onions, Garlic, Avocado, Citrus, Melons, Potatoes, Pomegranate, Passionfruit, Strawberry, Fresh Flowers and Leafy Greens.

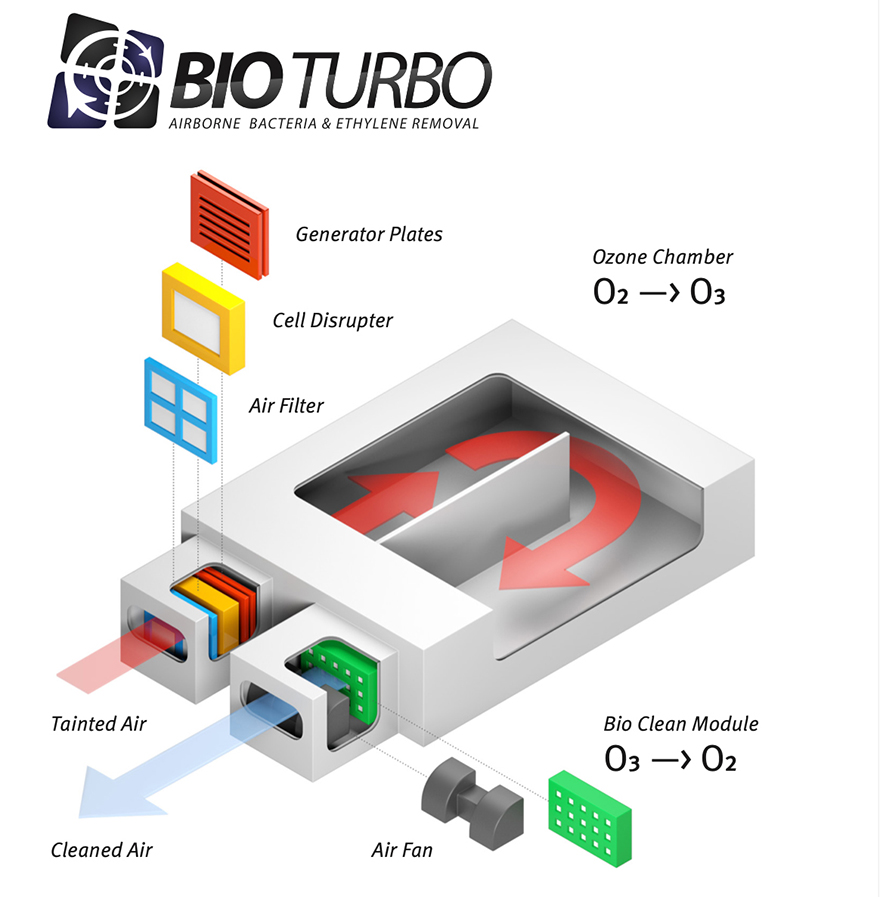

THE BIO TURBO SYSTEM

Extends storage life, significantly improves the lifespan and the quality of stored produce by cleaning storage atmosphere of airborne pathogens

- Prevents Premature Ripening

- Minimise rot and cross contamination

- Removes ethylene

- Utilises the power of ozone

- Kills Bacteria & Viruses

- Prevents Mould & Fungi

OUR PRODUCT RANGE

Humidity Controls

Transport & Walk-in Coolers

Product Misting & Ripening

Speak to the AUSPAC Biotechnologies team today!

Chat to us about extending your shelf life and produce quality